|

|

|

| About Us ¡@¡@ OEM/ODM | ¡@ |

|

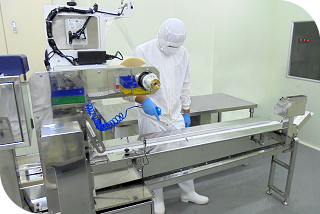

¡@ Environment The field is a food-grade clean room environment, the factory area to monitor the number of dust and bacteria on a regular basis to ensure the clean quality. All the factors are based on 10,000 grade clean room specifications (reference: FED-STD-209E¡G5£gm< 24,700¡A0.5£gm < 3,530,000). Totally match the Standard for Clean Operating Areas in Taiwan food GMP. ¡@ |

|

¡@ High level food machinery |

|||

| ¡@ | ¡@ | ¡@ | ¡@ |

¡¹ |

Imported Italian original equipment, consistently cooking process; accurately control the cooking temperature, humidity, time, and fully release the food flavor. |  ¡¶ France imported high-speed mixer |

|

¡¹ |

Using rapid freezing technology to deal with all ingredients, quickly cooled to -40¢XC, to maintain the original delicious taste of food. | ||

¡¹ |

Using continuous packaging equipment (MULTIVAC R105 high-speed packaging machine) and has a number of specifications meet the needs of different customers. | ||

¡¹ |

French original product (Robot Coupe high speed grinder), suitable for string whipping fruit juice, bean paste, powder and evenly mixed a variety of semi-solid, etc. | ||

¡¹ |

Large Popsicle maker with automatic filling system can quickly produce variety taste of the popsicles, and consistently maintain the product weight and volume. | ||

¡¹ |

Large cold storage and freezer can provide adequate storage space; maintain constant temperature and humidity and properly extend the shelf life of food. | ||

| ¡@ | ¡@ | ¡@ | ¡@ |

¡¶ Large micro bubble O3 system, completely wish out all the pesticides and microbes. |

¡¶ Clean room grade operating zone. All the additional water were Sterilized by O3 and UV. Washing water also equipped O3 micro bubble system. |

||

¡@ |

|||

|

¡@ Safety and health functional packaging materials All of the factory packaging materials, after several tests, can withstand high pressure sterilization (HPP) procedures, and can withstand -18¢XC long storage. |

||

¡· |

Multi-layer composite thermoplastic film, according to the product characteristics, with different packaging plastic films, can properly isolate the external smell, blocking microbial infection; keep the food the most complete flavor. | |

¡· |

Imported Japan Fujimori Kogyo industrial production of high-density PE containers. Through the highest standards of the production process, all the container pass the chemical dissolution test, so that the container can be directly exposed to raw milk, and maintain food stability. | |

| ¡@ | ¡@ | ¡@ |

¡¶ Completely clean popsicle packaging process |

¡¶ Raw material cutting area also upgrade to clean room grade place and equipped isolated air conditioner. |

|

¡@ |

||

|

¡@ OEM¡BODM |

|

| ¡@ | ¡@ |

|

¡° |

Our factory has large mixing equipment, can produce all kinds of bean paste, sauces, fruit juice and other products. Also we can follow customer demand for packaging, heating or HPP sterilization. |

|

¡° |

Equipped large steaming/roasting system, precisely follow customer needs to program the baking stages. |

|

¡° |

Large high speed packing machine with several different size modules that fit your selection to do vacuum packaging, nitrogen fill packaging and adjustable packaging. |

|

¡° |

We have popsicles making machine, clean room grade operating place and self-test of bacteria number which can protect food quality and safety for you. The Max producing number is 3,000 sticks per day. |

|

¡° |

Our company also offers various non-virus tissues culture seedling of sweet potato. You are most welcome to call for further question. |

|

|

|

| ¡@ | |

TAIWAN SWEET POTATO INTERNATIONAL FOOD CO., LTD

No.17, Lane 409,sec. I, Guangming Rd., Daliao Dist Kaohsiung City 831, Taiwan R.O.C

Ordering TEL¡G+886-7-7871215

Ordering FAX¡G+886-77878604

Toll-free Customer Service Line¡G0800-811-818

e-mail¡Gsweetpotato.smile@yahoo.com.tw

Facebook¡Ghttps://www.facebook.com/shesundae